Cov khoom

-

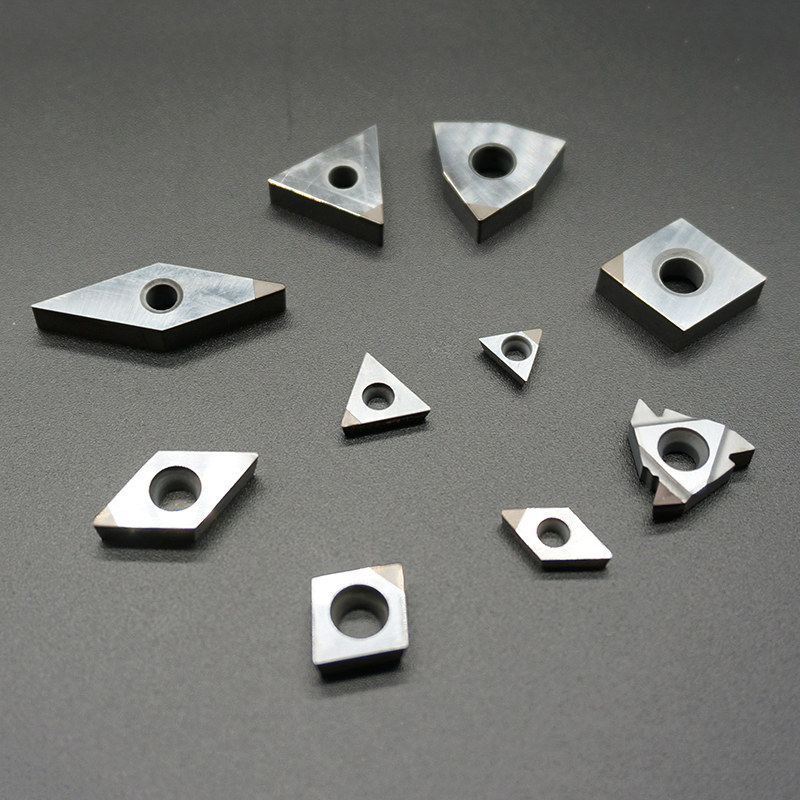

Rau Thaum tshav kub kub-Resistant Alloy

ISO txheem cov cuab yeej ua feem ntau ntawm kev lag luam hlau ua haujlwm machining. Cov ntawv thov sib txawv los ntawm kev ua tiav mus rau roughing.

-

Rau Aluminium & Copper

ISO txheem cov cuab yeej ua feem ntau ntawm kev lag luam hlau ua haujlwm machining. Cov ntawv thov sib txawv los ntawm kev ua tiav mus rau roughing.

-

PCD

ISO txheem cov cuab yeej ua feem ntau ntawm kev lag luam hlau ua haujlwm machining. Cov ntawv thov sib txawv los ntawm kev ua tiav mus rau roughing.

-

CBN

ISO txheem cov cuab yeej ua feem ntau ntawm kev lag luam hlau ua haujlwm machining. Cov ntawv thov sib txawv los ntawm kev ua tiav mus rau roughing.

-

Kauv Point Kais

Lub degree yog zoo dua thiab muaj peev xwm tiv taus ntau dua txiav quab yuam. Cov nyhuv ntawm kev ua cov hlau tsis-ferrous, stainless hlau, thiab ferrous hlau yog qhov zoo heev, thiab cov apex kais dej yuav tsum nyiam siv rau cov xov los ntawm qhov.

-

Ncaj Flute Kais

Qhov ntau yam, qhov txiav lub khob hliav qab tuaj yeem muaj 2, 4, 6 cov hniav, cov kais dej luv luv yog siv rau qhov tsis yog los ntawm qhov, cov kais dej ntev yog siv los ntawm lub qhov. Ntev npaum li lub qhov hauv qab yog qhov tob txaus, lub khob hliav qab yuav tsum tau ntev li ntev tau, kom cov hniav ntau dua yuav sib faib cov khoom txiav thiab kev pabcuam lub neej ntev dua.

-

Spiral Flute Kais

Vim lub helix lub kaum sab xis, qhov tseeb txiav rake lub kaum sab xis ntawm tus kais yuav nce raws li lub kaum sab xis helix nce. Kev paub qhia peb: Rau kev ua cov hlau ferrous, lub helix lub kaum sab xis yuav tsum me dua, feem ntau nyob ib ncig ntawm 30 degrees, kom ntseeg tau lub zog ntawm cov hniav helical thiab pab txuas lub neej ntawm cov kais dej. Rau kev ua cov hlau tsis-ferrous xws li tooj liab, txhuas, magnesium, thiab zinc, lub kaum sab xis helix yuav tsum loj dua, uas tuaj yeem nyob ib ncig ntawm 45 degrees, thiab kev txiav yog ntse dua, uas yog qhov zoo rau kev tshem tawm nti.

-

BT-ER tus tuav

Spindle qauv: BT/HSK

Khoom hardness: HRC56-58

Muaj tseeb roundness: ± 0.8mm

Zuag qhia tag nrho dhia qhov tseeb: 0.008mm

Khoom siv: 20CrMnTi

Dynamic ntsuas qhov ceev: 30,000

-

BT-C Powerful Holder

Khoom hardness: HRC56-60

Khoom siv: 20CrMnTi

Daim ntawv thov: dav siv hauv CNC machining chaw

Installation: yooj yim qauv; yooj yim rau nruab thiab dissemble

Muaj nuj nqi: Sab milling

-

BT-APU Integrated Laum Chuck

Khoom hardness: 56HRC

Khoom siv: 20CrMnTi

Zuag qhia tag nrho clamping: ± 0.08mm

Qhov tob ntawm qhov nkag: > 0.8mm

Txheem ceev ntawm kev sib hloov: 10000

Qhov tseeb roundness: ± 0.8u

Clamping ntau: 1-13mm / 1-16mm

-

BT-SLA Side Lock End Mill Holder

Khoom Hardness: > 56HRC

Khoom siv: 40CrMnTi

Zuag qhia tag nrho Clamping: <0.005mm

Qhov tob ntawm qhov nkag: > 0.8mm

Standard ceev ntawm kev sib hloov: 10000

-

Lub taub hau lub taub hau

Feem ntau siv raumachining chawthiabgantry milling tshuab. Ntawm lawv, lub teeb hom tuaj yeem ntsia tau rau hauv lub cuab yeej magazine thiab tuaj yeem hloov pauv dawb ntawm lub cuab yeej magazine thiab lub tshuab spindle; qhov nruab nrab thiab hnyav hom muaj ntau dua rigidity thiab torque, thiab yog haum rau feem ntau machining yuav tsum tau. Vim hais tias lub kaum sab xis lub taub hau nthuav qhov kev ua tau zoo ntawm lub tshuab cuab yeej, nws yog sib npaug rau ntxiv ib qho axis rau lub tshuab cuab yeej. Nws yog qhov ua tau zoo dua li qhov thib plaub axis thaum qee qhov loj workpieces tsis yooj yim rau tig los yog xav tau siab precision.