Self Centering Vise: Ib qho Precision Clamping Revolution Los Ntawm Aerospace mus rau Kev Kho Mob Manufacturing

Kev daws teeb meem nrog 0.005mm rov ua kom raug, 300% kev txhim kho hauv kev co, thiab 50% txo tus nqi kho.

Kab lus piav qhia:

I. Self centering Vise: Lub Revolutionary Value of Disrupting Traditional Clamping

Case 1: Ib lub tuam txhab muaj npe nrov automotive tivthaiv

Cov teeb meem tseem ceeb tau ntsib thaum siv lub vise:

1.Large concentricity sib txawv: cov tsoos vise clamping txoj kev ua rau ib tug concentricity yuam kev ntawm lub iav ntawm 0.03mm, uas tshaj qhov kam rau ua ntau yam (≤0.01mm), thiab cov seem seem yog siab li 15%.

2. Tsawg ntau lawm efficiency: Txhua daim yuav tsum tau 8 feeb rau clamping, thiab nquag hloov mus cuam tshuam cov kab ntau lawm atherosclerosis.

3.Surface quality instability: Cov kev vibration ua rau saum npoo roughness Ra mus fluctuate ntawm 0.6 thiab 1.2 μm, uas ua rau ib tug 30% nce nyob rau hauv polishing nqi.

Kev daws: Txhim kho ntawm tus kheej-centering vise technology

Core parameters ntawm Self Centering Vise:

Centering qhov tseeb: ± 0.005mm

Repeatability positioning raug: ± 0.002mm

Qhov siab tshaj plaws clamping quab yuam: 8000N

Hardened guide rails (HRC ≥ 60) muaj peev xwm tiv thaiv hnav

(Cov ntsiab lus no tuaj yeem ua tiav los ntawm Meiwhaself centering qhov muag.)

Cov kauj ruam tshwj xeeb rau kev hloov qhov self-centering vise:

1. Kev kho cov kab ntau lawm: Hloov cov tsoos vices ntawm 5 machining chaw thiab integrate lub xoom-point ceev-hloov system

2. Self centering vise nrog shark fin-zoo li lub puab tsaig tsim: Cov hniav tshwj xeeb txhim khu kev sib txhuam, txo cov kev co (kev vibration amplitude yog txo los ntawm 60%)

Lub breakthroughs tiav nyob rau hauv cov nqe lus ntawm precision, efficiency thiab nqi tom qab kho dua tshiab tus kheej centering vise.

| Index | Ua ntej kev txhim kho Tus Kheej centering vise | Tom qab kev txhim kho tus kheej-centering vise | Kev txhim kho feem pua |

| Coaxial yuam kev | 0.03mm ib | 0.008mm ib | 73% ↓ |

| Tib-thooj clamping lub sijhawm | 8 feeb | 2 min | 75% ↓ |

| Nto roughness Ra | 0.6-1.2 hli | Kev ruaj ntseg ≤ 0.4 μm | sib xws |

| Txhua xyoo pov tseg | 1.800.000 Nws | $450,000 | ¥ 1.35 lab khaws tseg |

| Txiav lub neej | Qhov nruab nrab, 300 yam khoom. | 420 khoom | 40% ↑ |

Tus nqi rov qab los rau tus kheej qhov chaw hloov kho tshiab: Cov cuab yeej siv peev yog ¥200,000, thiab tus nqi rov qab tsis pub dhau 6 lub hlis.

II. Cov txiaj ntsig tseem ceeb ntawm Tus Kheej qhov chaw nruab nrab vise Clamps: Triple Breakthrough hauv Precision, Efficiency thiab Flexibility

Qhov zoo ntawm tus kheej qhov chaw vise 1: Micrometer-theem qhov tseeb lav

Bidirectional ntsia hlau pas nrig synchronization tshuab: Tshem tawm unilateral offset, repeatability positioning raug ≤ 0.005mm (video ntawm dial indicator test)

Kev sib piv cov ntaub ntawv ntawm kev vibration tsis kam ntawm tus kheej centering vise thiab tsoos vise

| Txoj kev Clamping | Kev vibration amplitude (μm) | Nto roughness Ra (μm) |

| Kev lig kev cai | 35 | 1.6 |

| Self centering lwm | 8 | 0.4 |

Self centering vise kom zoo dua 2: Efficiency doubled by engine

Self centering saib Quick Change System:

Zero-point positioning enables 2-thib ob hloov ntawm workpieces

Lub puab tsaig modular txhawb nqa ib txhij clamping ntawm ntau pawg ntawm workpieces thaum ua.

Qhov chaw siv tau nce 40%: Qhov chaw qis, siab tsim (100 - 160mm), ua kom 5 workpieces ua tiav ib txhij

Self centering vise grips kom zoo dua 3: Core ntawm saj zawg zog ntau lawm

Universal adaptability:

Hard claws: Clamping steel qhov chaw / castings (sib haum nrog ntxhib nto)

Mos Claws: Customized Silicone Lub puab tsaig npog rau kev tiv thaiv nto ntawm kev kho mob cog

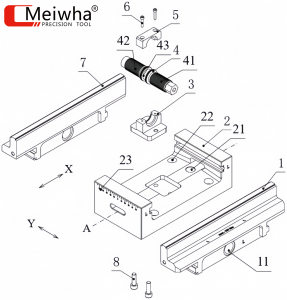

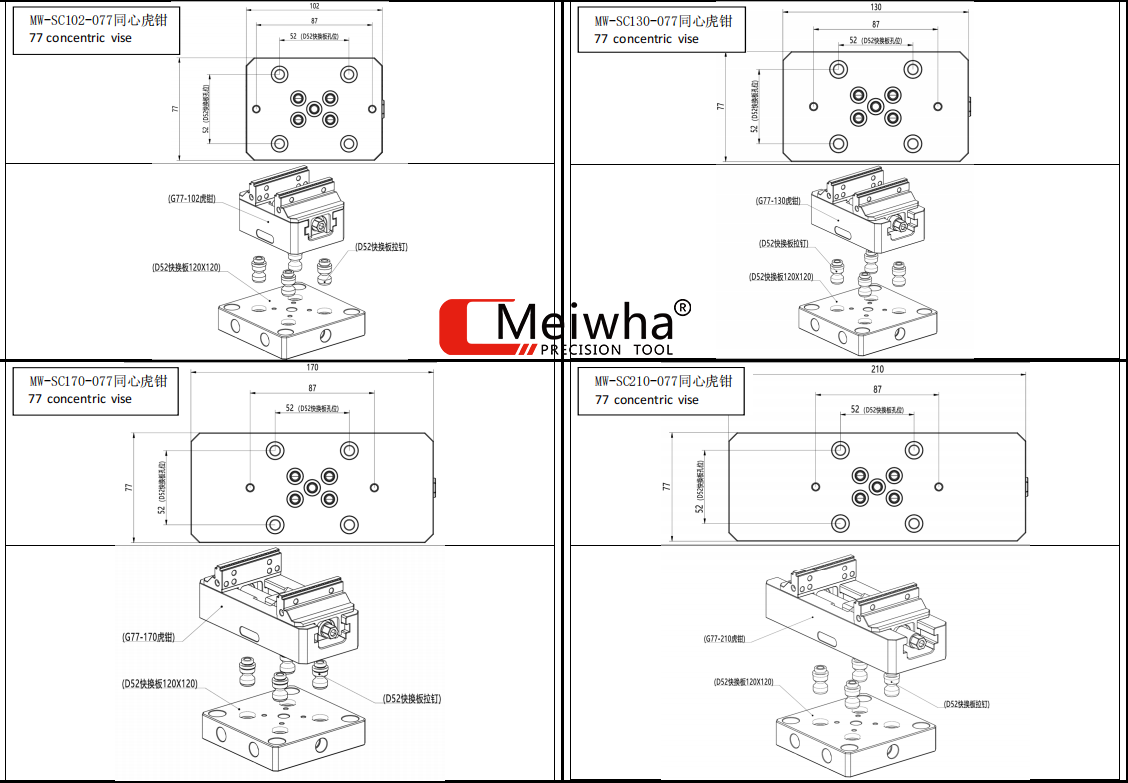

Self Centering Vise Scheme Layout Diagram

III. Rau Daim Ntawv Thov Scenarios thiab Kev Xaiv Cov Piv txwv ntawm Self centering vise

| Kev lag luam | Tej workpiece | Sikution | nyhuv |

| Aerospace | Titanium alloy tis ribs | High-frequency induction cua sov vise + ceramic-coated puab tsaig | Deformation <0.01mm, lub cuab yeej lub neej ob npaug |

| Kev kho mob implantation | Lub hauv caug Prosthesis | Pneumatic self-center vise + Kho mob-qib lub puab tsaig muag | Nto tsis muaj khawb, tawm los → 99.8% |

| Lub zog tshiab tsheb | Roj teeb lub cev | Strengthened rigid hydraulic vise (anti-vibration qauv) | Kev ua haujlwm vibration yog txo los ntawm 60%, thiab lub sijhawm ua haujlwm yog txo los ntawm 35%. |

| Precision electronics | Txawb xov tooj nruab nrab ncej | Miniature self-center vise (φ80mm stroke) | Thaj tsam txo los ntawm 70%, qhov tseeb ± 0.003mm |

IV. Phau Ntawv Qhia Txog Kev Saib Xyuas Tus Kheej Rau Tus Kheej Vise : tuaj yeem txuas rau Tus Kheej Qhov Chaw Pabcuam Lub Neej

1. Daim Ntawv Teev Kev Kho Mob Txhua Hnub rau Tus Lwm Thawj Coj:

| Self centering vise Cheebtsam | Cov qauv ua haujlwm |

| Lead ntsia hlau qhia rail | Txhua hnub cua phom tshem tawm plua plav + Txhua lub limtiam roj txhaj tshuaj |

| Clamping nto tiv thaiv cheeb tsam | Cawv tshem tawm cov dej txiav uas tseem tshuav |

| Tsav tsheb mechanism | Kev tshuaj xyuas txhua hli ntawm cov roj txoj kev sealing kev ua tau zoo (siab ≥ 0.6 MPa) |

2. Peb ua thiab ua tsis tau rau kev tswj tus kheej qhov chaw

1.Siv ib tug hlau txhuam los ntxuav cov kev taw qhia rail → ua rau khawb ntawm qhov precision nto

2. Kev sib xyaw lubricants ntawm cov viscosities sib txawv → Yuav ua rau gelation thiab txhaws

3. Tshaj qhov ntsuas clamping quab yuam los ntawm 50% → yuav ua rau deformation mus tas li

Post lub sij hawm: Aug-09-2025