Lub hwj chim ruaj khov magnetic chuck, raws li qhov ua tau zoo, txuag hluav taws xob thiab ua haujlwm yooj yim rau kev tuav cov khoom ua haujlwm, yog siv dav hauv ntau yam xws li kev ua hlau, sib dhos, thiab vuam. Los ntawm kev siv cov hlau nplaum tas mus li los muab lub zog nqus dej tsis tu ncua, lub zog ruaj khov hlau nplaum nqus lub khob ua kom muaj txiaj ntsig zoo, txuag sijhawm thiab nqi. Kab lus no yuav muab cov ncauj lus qhia ntxaws ntxaws txog cov qauv txheej txheem, cov khoom lag luam zoo, kev txwv kev siv thiab kev saib xyuas ntawm lub khob nqus hlau nplaum muaj zog, pab cov neeg siv nkag siab zoo dua thiab siv cov cuab yeej no.

I. Cov Ntsiab Cai ntawm Lub Hwj Chim Nyob Ib Txhis Magnetic Chuck

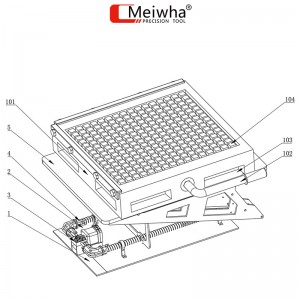

Chuck Internal Structure Diagram

1.Peb-dimensional magnetic circuit superposition tsim

- Ob-txheej magnetic ncej qauv:

Ib txheej sib nqus ob txheej yog tsim los ntawm kev siv lub inverted T-shaped core thiab ib sab-dej phaj. Neodymium-hlau-boron sib nqus hlau (nrog N ncej taw qhia) thiab hauv qab aluminium-nickel-cobalt magnetic steel tsim peb txoj kev ywj pheej kaw. Cov kab hluav taws xob sib nqus circulate los ntawm cov tub ntxhais → workpiece → phaj txheej → phaj hauv qab → cov tub ntxhais, yog li ua kom cov hlau nplaum sib nqus ntau dua 16%.

- Sib nqus centripetal tsom:

Lub inverted T-shaped core converges sib nqus kab ntawm cov npoo ntawm qhov chaw, hais txog qhov teeb meem ntawm tsis txaus adhesion rau nqaim workpieces (xws li cov lus qhia thiab cov hniav), thiab qhov tsawg tshaj plaws ua hauj lwm workpiece loj ncav cuag 50 × 50 × 2mm.

2.Halbach Array Txhim Kho

- Hla-shaped mus tas li magnet array:

Tus qauv high-end txais yuav ob-dimensional "cross" hom Halbach array. Los ntawm cov txheej txheem tshwj xeeb ntawm cov hlau nplaum ruaj khov (nrog NS ncej hloov pauv), nws tswj hwm kev coj ua ntawm cov hlau nplaum, ua kom cov hlau nplaum sib nqus ntawm ib sab ntawm qhov chaw ua haujlwm los ntawm 50% thiab txo cov xau sib nqus los ntawm 30%.

- Optimization ntawm Magnetic Energy Utilization Rate:

Nyob rau hauv tib lub ntim, Halbach array nce qhov sib nqus quab yuam los ntawm 120N / cm² hauv cov qauv tsim rau 180N / cm², thaum txo cov khoom siv los ntawm 20%.

| Hom khoom siv hlau nplaum | lub luag haujlwm tseem ceeb | kev ua haujlwm parameter | daim ntawv thov scenarios |

| NdFeB (neodymium hlau boron) | Siab coercivity (≥ 955 kA / m) anti-demagnetization muaj peev xwm | Remanent hlau nplaum Br = 1.26 - 1.29 T | Lub ntsiab sib nqus ncej kom muaj zog adhesion. |

| Aluminium-nickel-cobalt | High residual magnetism (Br = 1.3T) txhim khu lub zog magnetic teb | Ua haujlwm kub ≤ 460 ℃ | Pab sib nqus ncej, txhim khu thermal stability |

| LNG ruaj khov hlau nplaum | Variable polarity, teb rau hluav taws xob tswj cov cim | Retentive zog: 56 kA / m | Sib nqus Circuit Court switching execution txheej |

Synergistic nyhuv: NdFeB muab kev tiv thaiv-demagnetization muaj peev xwm, AlNiCo txhim khu lub magnetic teb nkag mus rau lub zog, LNG enables polarity reversal. Peb lub ntsiab lus tshem tawm qhov sib txawv muaj peev xwm sib nqus los ntawm qhov tsis sib nqus sib nqus, kom ntseeg tau tias cov hlau nplaum seem mus zero thaum lub sijhawm demagnetization.

II. Khoom zoo ntawm High-Intensity Permanent Magnetic Chuck

Tshuab CNC Chuck

1.Tsis xav tau lub hwj chim sab nraud

Lub zog ruaj khov hlau nplaum Chuck muab lub zog ruaj khov los ntawm cov hlau nplaum ruaj khov thiab tsis xav tau lub zog siv. Rau qee qhov chaw ua haujlwm uas nyob deb ntawm qhov chaw siv hluav taws xob lossis qhov chaw tsis yooj yim siv hluav taws xob, cov hlau nplaum ruaj khov muaj cov kev daws teeb meem yooj yim heev.

2.Quick Installation thiab Disassembly

Piv nrog cov tsoos mechanical fixtures los yog electromagnetic suction khob, lub hwj chim mus tas li magnetic chuck muaj ib tug ceev installation thiab disassembly ceev. Nrog kev ua haujlwm yooj yim xwb, lub workpiece tuaj yeem kho lossis tso tawm, yog li txhim kho cov kab ntau lawm. Lawv tshwj xeeb tshaj yog haum rau kev ua haujlwm ib puag ncig uas cov workpieces yuav tsum tau hloov ntau zaus.

3.Stable suction ua kom cov khoom raug

Cov hlau nplaum muaj zog ruaj khov chuck muab kev sib txuam thiab ruaj khov adhesion quab yuam, tiv thaiv lub workpiece los ntawm kev txav los yog vibrating thaum lub sij hawm ua, yog li txhim kho qhov tseeb thiab efficiency. Nws yog tshwj xeeb tshaj yog haum rau precision ua.

4.Txuag nqi chaw

Vim tias tsis muaj lub zog siv hluav taws xob thiab kev tswj hwm txoj hauv kev, cov khoom siv hluav taws xob ruaj khov muaj zog feem ntau yog tsim los ua kom muaj zog ntau dua, ua rau lawv tsim nyog rau cov chaw ua haujlwm nrog qhov chaw tsawg. Ntxiv mus, lawv cov nqi kho mob qis dua thiab kev pab cuam lub neej ntev tuaj yeem txo cov nqi tsim khoom tag nrho.

5.Highly adaptable, haum rau ntau yam workpieces

Lub zog ruaj khov hlau nplaum chuck tsis tuaj yeem tsuas yog tuav cov hlau ua haujlwm ib txwm muaj, tab sis kuj hloov mus rau ntau yam duab thiab qhov ntau thiab tsawg ntawm workpieces. Nws tuaj yeem kho cov ntaub ntawv tsis sib xws thiab tuab tuab, ua tau raws li cov txheej txheem sib txawv. (Ib feem, customizable magnet ncej teeb yog npaj kom txaus siab)

III. Txwv tsis pub siv High-Intensity Permanent Magnetic Chuck

Txawm hais tias muaj zog sib nqus chuck muaj kev siv dav hauv kev tsim khoom, cov neeg siv tseem yuav tsum paub txog cov kev txwv hauv qab no thaum siv lawv, txhawm rau tiv thaiv cov khoom puas lossis kev ua haujlwm tsis zoo.

1. Zam txhob raug qhov kub thiab txias ntev.

Qhov kub thiab txias yuav ua rau cov khoom sib nqus ntawm cov hlau nplaum ruaj khov kom maj mam tsis muaj zog. Tshwj xeeb tshaj yog rau cov hlau nplaum uas tsis tshua muaj lub ntiaj teb ua tau zoo, qhov ntev ntawm qhov raug rau ib puag ncig dhau ntawm lawv qhov kev ua haujlwm kub yuav ua rau txo qis zog nqus. Yog li ntawd, muaj zog mus tas li hlau nplaum chuck yuav tsum tsis txhob siv nyob rau hauv kev ua hauj lwm ib puag ncig nrog kub siab heev.

2.Tsis txhob sib cuag nrog cov khoom sib nqus muaj zog

Lub zog ruaj khov magnetic chuck twb muaj zog sib nqus ntawm nws tus kheej. Yog tias nws los rau hauv kev sib cuag nrog lub zog sib nqus, nws yuav ua rau lub zog sib nqus kom txo qis lossis ua rau lub khob nqus dej puas. Nws yog ib qho tsim nyog los xyuas kom meej tias qhov muaj zog sib nqus chuck yog khaws cia kom deb ntawm cov khoom siv hluav taws xob, cov khoom siv high-frequency, thiab lwm yam.

3. Tsis txhob sib cuag ncaj qha nrog cov tshuaj corrosive

Cov tshuaj corrosive xws li cov kua qaub muaj zog thiab cov hauv paus muaj zog tuaj yeem cuam tshuam rau saum npoo ntawm cov hlau nplaum mus tas li, ua rau nws cov khoom sib nqus kom txo qis lossis puas. Thaum lub sijhawm ua haujlwm, nws yog ib qho tsim nyog kom tsis txhob muaj lub khob nqus dej los ntawm kev sib cuag nrog cov tshuaj no ntev, tshwj xeeb tshaj yog cov uas tsis muaj kev tiv thaiv.

4. Zam kev siv ntau dhau

Txawm hais tias lub zog ruaj khov magnetic chuck muab lub zog nqus loj, nws kuj muaj qhov txwv nqa. Kev siv ntau dhau yuav ua rau muaj kev sib nqus sib nqus thiab txawm tias muaj kev puas tsuaj rau cov qauv chuck, ua rau muaj kev nyab xeeb. Yog li ntawd, thaum siv nws, qhov tsim nyog qhov hnyav ntawm lub workpiece yuav tsum raug xaiv raws li qhov tshwj xeeb ntawm chuck.

IV. Txoj kev tu kom muaj zog ruaj nrees hlau nplaum chuck

Kev tu kom zoo tuaj yeem tsis tsuas yog txuas lub neej kev pab cuam ntawm lubhaib ruaj khov magnetic chuck, tab sis kuj tuav nws cov nyhuv adhesion. Nov yog qee qhov kev saib xyuas zoo:

1. Kev tu tsis tu ncua

Qhov saum npoo ntawm chuck yuav tsum tau ntxuav tsis tu ncua kom tsis txhob muaj cov hlau shavings, roj stains lossis lwm yam khib nyiab. Qhov no tseem ceeb tshwj xeeb tshaj yog thaum lub sij hawm ua hlau. Koj tuaj yeem ntxuav qhov chaw siv cua compressed los yog ntaub mos. Nws tsis pom zoo kom siv cov khoom tawv los txhuam nws, vim qhov no yuav ua rau cov hlau nplaum puas.

2. Tsis tu ncua xyuas cov hlau nplaum

Txawm hais tias cov hlau nplaum ruaj khov chucks tsis tso siab rau lub zog sab nraud, lawv lub zog sib nqus tseem yuav maj mam tsis muaj zog thaum lub sijhawm siv nce ntxiv. Nws yog ib qho tsim nyog yuav tsum tsis tu ncua xyuas lub zog nqus ntawm lub khob nqus dej kom ntseeg tau tias lawv nyob twj ywm ntawm qhov qub. Yog tias lub zog nqus tau raug txo qis, kev txiav txim siab yuav tsum tau muab los hloov cov hlau nplaum los yog kev saib xyuas.

3. Zam kev sib tsoo hnyav

Cov hlau nplaum nyob rau hauv lub zog ruaj khov magnetic chuck yog fragile. Kev cuam tshuam loj tuaj yeem ua rau cov hlau nplaum tawg lossis lub zog sib nqus ua tsis tiav. Thaum lub sijhawm ua haujlwm, ib tus yuav tsum tau ceev faj kom tsis txhob muaj kev sib tsoo tsis tsim nyog.

Covhaib ruaj khov magnetic chuck, nrog nws qhov zoo xws li tsis xav tau lub zog siv hluav taws xob, kev teeb tsa sai thiab kev tshem tawm, thiab lub zog nqus dej ruaj khov, tau dhau los ua cov cuab yeej tseem ceeb hauv kev tsim khoom niaj hnub no. Nrog rau kev siv thiab kev saib xyuas kom zoo, nws tuaj yeem txhim kho kev tsim khoom thiab ua kom raug. Kev nkag siab txog nws cov ntsiab cai, qhov zoo, nrog rau kev siv thiab kev saib xyuas kom raug yog tus yuam sij kom ntseeg tau tias nws lub sijhawm ua haujlwm tau zoo.

cov ntaub ntawv siv:

Sib nqus Clamping Technology- Qhia txog kev lag luam sib nqus clamps thiab lawv daim ntawv thov.

Muaj Magnetism- Lub hauv paus ntawm cov hlau nplaum ruaj khov siv rau hauv cov cuab yeej siv.

Nco tseg: Cov khoom lag luam tshwj xeeb tsis yog raws li cov ntaub ntawv tshiab los ntawm cov chaw tsim khoom. Thov mus saib peb lub chaw tsim khoom kom paub ntau ntxiv txog cov qauv lossis thov daim ntawv qhia xaiv!

Post lub sij hawm: Aug-14-2025