HSS Drills

Meiwha Laum Cov cuab yeej muaj HSS Laum thiab Alloy Drill.The HSS Twist Laum ntsis av yog rau drilling los ntawm cov hlau nrog qhov siab tshaj plaws. Lub me ntsis nthuav tawm 135-degree tus kheej-centring split-point tip combines active txiav thiab zoo meej centering tsis wandering, xa siab tshaj plaws precision. Cov ntsiab lus sib cais tseem tshem tawm qhov xav tau ua ntej punch lossis pilot xyaum mus txog 10 mm. Qhov no precision-av me ntsis ua los ntawm HSS (high-speed steel) enables mus txog 40% ceev drilling tus nqi thiab mus txog rau 50% qis pub siab tshaj tus qauv-hauv av HSS laum khoom nrog chisel npoo. Qhov no me ntsis yog tsim los rau drilling qhov nyob rau hauv alloyed thiab non-alloyed steel, cam khwb cia hlau, cam khwb cia hlau, sintered hlau, malleable cam khwb cia hlau, non-ferrous hlau thiab hard plastics. Nws muaj lub cylindrical shank system (shank sib npaug rau lub laum me ntsis txoj kab uas hla) thiab yog npaj rau siv nyob rau hauv laum stands thiab xyaum tsav tsheb.

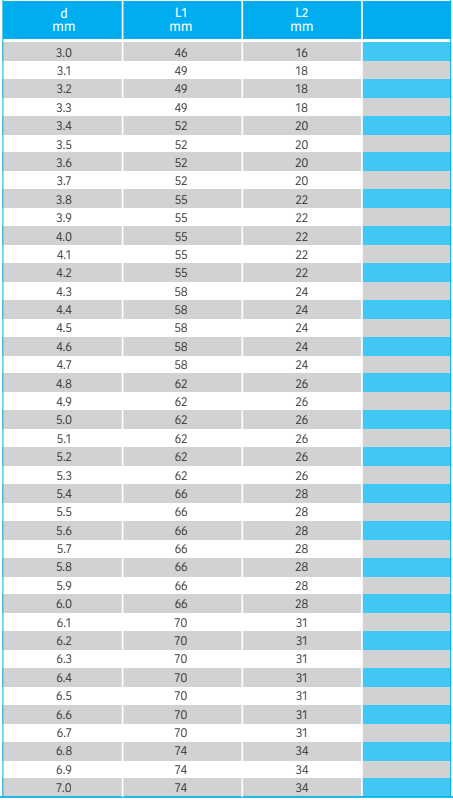

HSS Twist Drill Bit Ground yog tsim los rau DIN 1897. Lub laum ntsis yog hom N (flute lub kaum sab xis) nrog 118-degree taub hau thiab ib txoj kab uas hla ntawm h8.

Kev ceev faj rau kev siv cov cuab yeej cemented carbide

1) Cemented carbide yog cov khoom siv tawv thiab nkig, uas yog nkig thiab puas nyob rau hauv kev quab yuam ntau dhau los yog qee qhov kev ntxhov siab hauv zos, thiab muaj cov npoo ntse.

2) Feem ntau ntawm cov cemented carbides feem ntau yog tungsten thiab cobalt. Cov khoom xyaw muaj qhov ntom ntom ntom ntom, yog li lawv yuav tsum tau ua raws li cov khoom hnyav thaum thauj thiab khaws cia.

3) Cemented carbide thiab steel muaj sib txawv thermal expansion coefficients. Txhawm rau tiv thaiv kev ntxhov siab los ntawm kev tawg, yuav tsum tau them nyiaj rau vuam ntawm qhov kub thiab txias.

4) Carbide txiav cov cuab yeej yuav tsum tau muab cia rau hauv qhov chaw qhuav, kom deb ntawm qhov chaw corrosive.

5) Thaum lub sij hawm txiav cov cuab yeej cemented carbide, chips, chips, thiab lwm yam yuav tiv thaiv tsis tau. Thov npaj cov khoom siv tiv thaiv kev ua haujlwm tsim nyog ua ntej machining.

6) Yog tias cov khoom siv txias txias lossis cov khoom siv plua plav yog siv rau hauv cov txheej txheem txiav, hauv kev txiav txim siab ntawm lub neej kev pab cuam ntawm lub tshuab cuab yeej thiab cov cuab yeej txiav, thov siv cov khoom siv txiav cov dej los yog cov khoom siv plua plav kom raug.

7) Thov nres siv lub cuab yeej nrog cov kab nrib pleb thaum ua haujlwm.

8) Carbide txiav cov cuab yeej yuav ua npub thiab poob lub zog vim siv mus ntev. Thov tsis txhob cia cov uas tsis yog cov kws tshaj lij ua kom lawv ntse.

9) Thov khaws cov cuab yeej siv hlau tsis huv thiab cov khoom tawg ntawm cov cuab yeej hlau kom zoo kom tsis txhob muaj kev puas tsuaj rau lwm tus.